What Is a Pickleball Made Of? A Comprehensive Guide

What Is a Pickleball Made Of?

A pickleball is primarily made of a durable plastic polymer, such as polypropylene or polyethylene, which forms the ball’s core and provides the desired bounce and performance. The ball’s surface features a carefully designed pattern of drilled holes that enhance its aerodynamics and flight characteristics. Pickleballs must adhere to specific size and weight regulations set by the USA Pickleball Association (USAPA) to ensure consistent play across all skill levels. The manufacturing process of pickleballs involves advanced techniques like rotational molding and injection molding, which create a seamless, uniform shape and allow for precise control over the ball’s hardness, feel, and overall quality.

Key Takeaways

- Pickleballs are predominantly made of hard plastics like polypropylene and polyethylene, which offer durability and optimal bounce.

- The USAPA sets specific size (2.87 to 2.97 inches in diameter) and weight (0.78 to 0.935 ounces) specifications for pickleballs to ensure consistent play.

- Pickleball manufacturing processes include rotational molding for uniform shape and injection molding for precise shaping and smooth finishes.

- Different pickleball brands offer unique features, such as variations in materials, hole patterns, and performance characteristics for indoor and outdoor play.

- The hardness, feel, and hole size of a pickleball significantly impact its performance, with indoor and outdoor balls having slight differences to accommodate court surfaces.

- As pickleball continues to evolve, players can expect further innovations in ball composition, customizable features, and smart technology integration.

By understanding the materials, construction methods, and performance factors of pickleballs, players can make informed choices when selecting the right ball for their playing style and court conditions. Embrace the unique characteristics of your chosen pickleball and let it elevate your game to new heights!

The Core Components of a Pickleball

Material Breakdown

At the heart of every pickleball lies a core predominantly made of hard plastic. The specific plastic types used in pickleball construction often include:

- Polypropylene (PP): Known for its rigidity and longevity, polypropylene is a popular choice due to its durability and performance characteristics, according to a credible source on pickleball materials.

- Polyethylene: Another common material used in pickleball cores, offering a perfect balance of durability and bounce, ensuring that the ball maintains its shape and responsiveness over time.

These plastics contribute to the overall feel and performance of the pickleball during play. The pickleball’s shell may also have additional additives or treatments to enhance its characteristics, such as:

- Texturization: Some pickleballs feature texturization on the surface to improve grip, as mentioned by a credible source on pickleball materials. This texturization can help players maintain better control over the ball during serves and rallies.

Another essential aspect of a pickleball’s construction is its hole pattern. The drilled holes on the surface of the ball serve to improve its aerodynamics. The typical number and arrangement of holes can vary between different pickleball brands and models, each offering a unique playing experience.

Pickleball Size and Weight Specifications

To ensure consistent play and fairness, pickleballs must adhere to specific size and weight specifications set by the USA Pickleball Association (USAPA):

| Specification | Measurement |

|---|---|

| Diameter | 2.87 to 2.97 inches |

| Weight | 0.78 to 0.935 ounces |

- The official size of a pickleball is between 2.87 and 2.97 inches in diameter, allowing for slight variations among different brands while maintaining a standard that players can rely on.

- In terms of weight, the USAPA specifies that a pickleball should weigh between 0.78 and 0.935 ounces, with the typical range falling between 0.78 and 0.88 ounces.

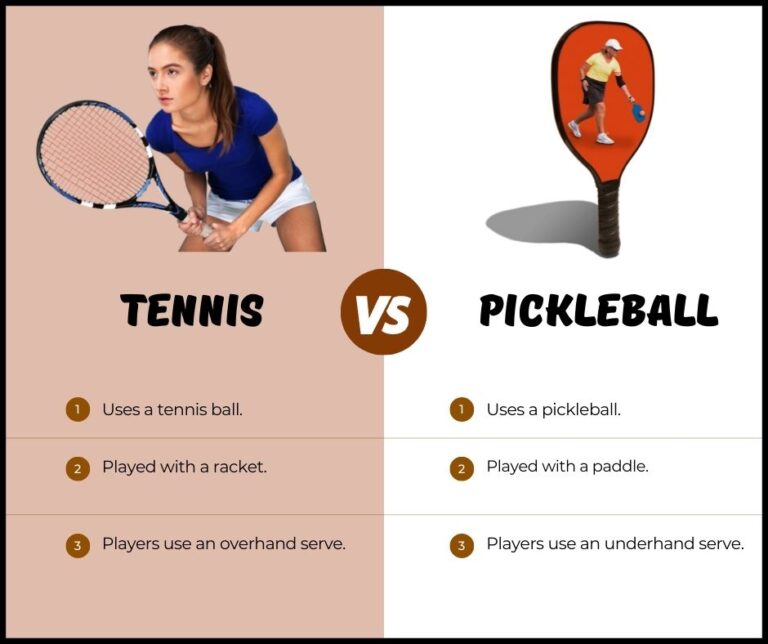

The weight of a pickleball can influence its bounce height and overall speed during a game. To put these specifications into perspective, it’s helpful to compare pickleballs to other sports balls:

- A pickleball is slightly larger than a table tennis ball but smaller than a tennis ball.

- This unique size and weight combination contributes to the distinct playing style and pace of pickleball.

Construction Methods

The Manufacturing Process

The creation of a pickleball involves several manufacturing processes, each contributing to the ball’s final form and performance:

- Rotational Molding:

- One common method for creating consistent and seamless pickleballs.

- Plastic powder is heated and formed within a mold, resulting in a uniform shape and thickness.

- A credible source on pickleball manufacturing highlights the importance of rotational molding in achieving a high-quality finished product.

- Injection Molding:

- Another manufacturing method used in pickleball production.

- Involves melting plastic and injecting it under pressure into a mold cavity.

- Allows for precise shaping and potentially smoother finishes on the pickleball’s surface.

- Particularly useful for creating the hollow interior of the ball.

Once the pickleball’s core is formed, the next step is drilling the holes. Precision and consistency in hole placement are crucial factors in determining the ball’s performance. The number, size, and arrangement of holes can impact the ball’s aerodynamics and overall behavior during play.

Impact of Material on Performance

Pickleball Brands and Their Unique Features

With the growing popularity of pickleball, numerous brands have emerged, each offering their own unique take on pickleball construction. Some of the most popular pickleball brands include:

- Dura

- Onix

- Franklin

These brands differentiate themselves through variations in materials, hole patterns, and overall performance characteristics. One notable distinction among pickleball brands is the difference between indoor and outdoor pickleballs:

- Indoor pickleballs: Typically designed with larger holes for better control and slower play, suitable for the smooth surfaces of indoor courts.

- Outdoor pickleballs: Often feature more numerous and smaller holes to enhance wind resistance and maintain stability in outdoor playing conditions.

Durability and bounce variations are also factors that set pickleball brands apart:

- Some brands prioritize durability, using high-quality materials and construction methods to create long-lasting balls.

- Others focus on optimizing the bounce and responsiveness of the ball, catering to players who prefer a livelier playing experience.

Hardness and Feel

The hardness of a pickleball directly affects its responsiveness and overall feel during play:

- Harder pickleballs: Offer a more crisp and lively response.

- Softer pickleballs: Provide a more muted and controlled feel.

The choice between harder and softer pickleballs often comes down to personal preference and playing style. Interestingly, indoor and outdoor pickleballs often have slight hardness variations to accommodate different court surfaces:

- Indoor courts: Typically made of smooth materials like wood or polyurethane, pair well with softer pickleballs for better control.

- Outdoor courts: Often feature rougher surfaces like concrete or asphalt, requiring harder pickleballs to maintain bounce and durability.

Number and Size of Holes

The number and size of holes on a pickleball play a significant role in its performance. These holes contribute to the ball’s weight, air resistance, and ultimately, its behavior during play:

- Indoor pickleballs: Typically have larger holes for better control, according to a credible source on pickleball ball types.

- Outdoor pickleballs: Might have more, smaller holes for improved wind resistance.

The arrangement of holes on a pickleball’s surface can also impact its flight characteristics:

- Some brands experiment with different hole patterns to optimize aerodynamics and create a unique playing experience.

- The placement and spacing of holes can affect the ball’s stability, spin, and overall trajectory.

The Evolution of Pickleball Design

Pickleball has come a long way since its humble beginnings. The early days of pickleball saw players using wooden paddles and modified wiffle balls. As the sport gained popularity, manufacturers began to experiment with different materials and designs to enhance performance and durability.

One of the most significant advancements in pickleball design has been the development of high-performance plastic polymers. These materials offer:

- Improved strength

- Bounce consistency

- Overall longevity compared to the wooden paddles and balls of the past

Modern manufacturing techniques, such as rotational and injection molding, have also contributed to the creation of higher-quality pickleballs.

As pickleball continues to evolve, we can expect to see further innovations in ball composition and performance. Manufacturers are constantly seeking ways to optimize the balance between speed, control, and durability. Some potential future developments could include:

- Use of eco-friendly materials

- Customizable hole patterns

- Smart technology integration for tracking and analysis

Frequently Asked Questions

- Are all pickleballs made of the same materials?

- While most pickleballs share similar core materials like polypropylene and polyethylene, there can be variations in the specific plastic blends and additives used by different manufacturers.

- These variations contribute to the unique characteristics and performance of each brand’s pickleballs.

- How long does a typical pickleball last?

- The lifespan of a pickleball depends on various factors, including the quality of materials, frequency of use, and playing conditions.

- On average, a well-constructed pickleball can last for several games or practice sessions.

- Signs of wear and tear, such as cracks or dents, indicate that it’s time to replace the ball.

- Can weather conditions affect a pickleball’s performance?

- Absolutely! Weather conditions can have a significant impact on a pickleball’s behavior.

- Factors like temperature, humidity, and wind can all influence the ball’s bounce, speed, and overall performance.

- Outdoor pickleballs are designed to withstand and adapt to these variables better than indoor balls.

Conclusion

Understanding what a pickleball is made of is essential for players looking to elevate their game and appreciate the intricacies of this captivating sport. From the core materials like polypropylene and polyethylene to the carefully designed hole patterns, every aspect of a pickleball’s construction contributes to its performance on the court.

The manufacturing processes, such as rotational and injection molding, play a crucial role in creating consistent and high-quality pickleballs. The impact of materials on performance, including factors like hardness, feel, and hole size, allows players to choose the perfect ball for their playing style and court preference.

With the rapid growth and evolution of pickleball, we can anticipate exciting advancements in ball design and technology. As manufacturers continue to innovate and push the boundaries of performance, players can look forward to an even more dynamic and enjoyable pickleball experience.

So, the next time you step onto the pickleball court, take a moment to appreciate the humble yet meticulously crafted pickleball. Embrace the unique characteristics of your chosen ball and let it inspire you to unleash your full potential as a player. Remember, the right pickleball can make all the difference in your game, so choose wisely and have fun!